BVS Classifier

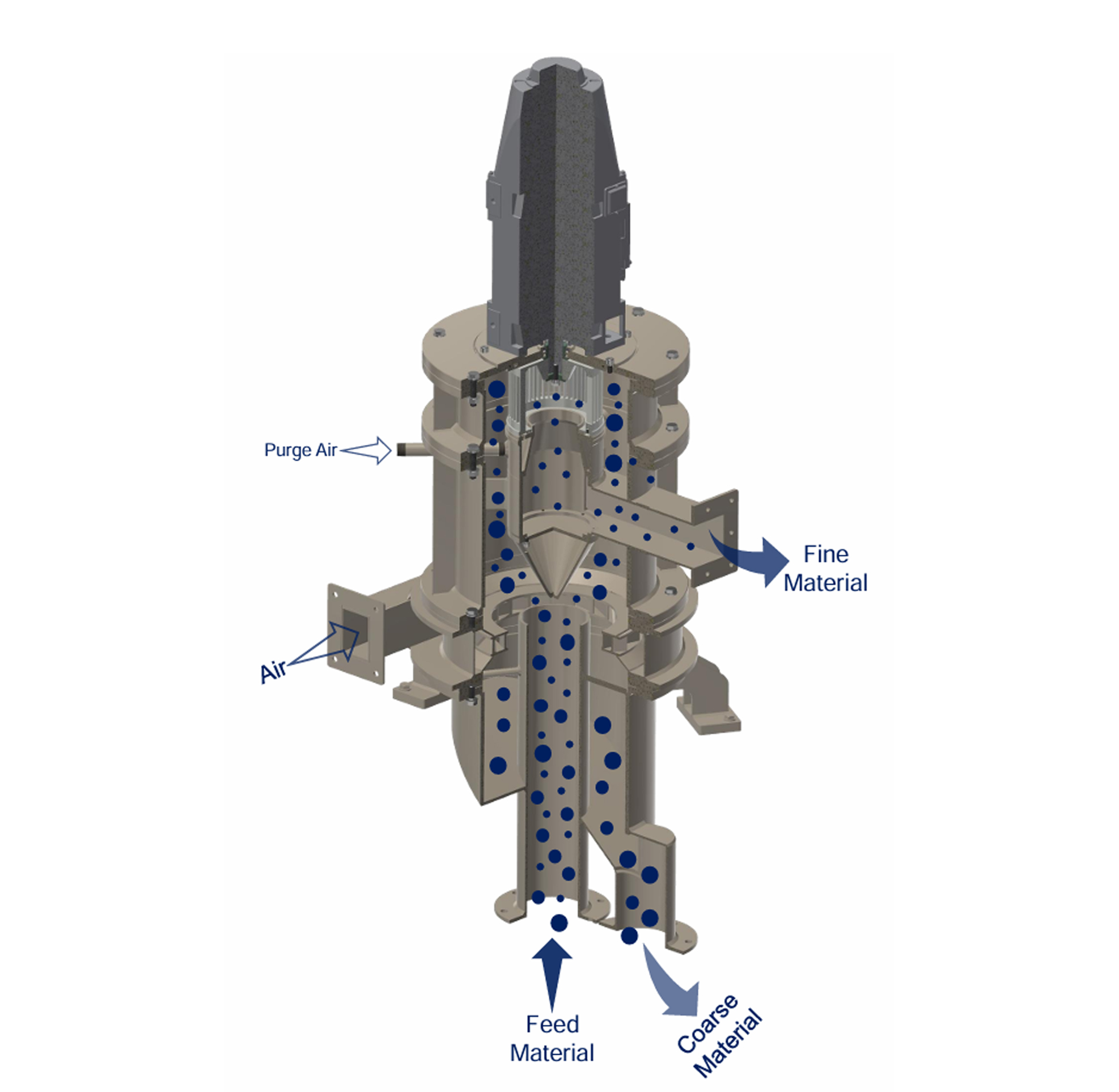

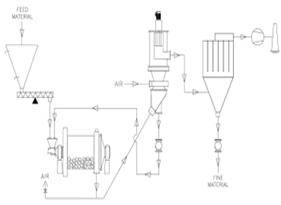

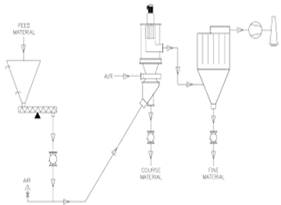

BVS air classifier technology is a widely used separation method, especially in applications where extracting very fine particles from bulk material. The BVS air classifier is a high-efficiency, air-swept, centrifugal force classifier designed for dry materials between 10 to 100 microns. The design is customized to suit the process. The BVS classifiers can operate independently with feeder, fan, and filter equipment, or in a closed circuit within a conventional milling system. The BVS classifier can be mounted in existing air systems with minimal modifications and achieves precise fineness across a wide feed range.

• Controlled grain size d97 10-100 microns.

• High efficiency with vertical rotor arrangement and sharp cut accuracy.

• Compact footprint; enclosed, dust-free, and low noise — environmentally friendly.

• Easy commissioning and operation.

• Available in industrial, pilot, and lab sizes.

• Wear protection options: steel, stainless, PU, or ceramic (Al₂O₃).

• Pressure-resistant up to 8 bar or pressure-shock proof.

The feed material enters the classifier with the main airflow, allowing direct pneumatic feed integration for efficiency. The rotor is belt-driven or directly motor-driven, with adjustable speed via frequency converter to control particle size on the fly. Fine particles below the cut point pass through the rotor and are collected in filters. Coarse particles are rejected and discharged, with secondary air generating a vortex flow that improves sharpness and fine yield.

| BVS | Tip | BVS150 | BVS200 | BVS315 | BVS500 | BVS650 |

|---|---|---|---|---|---|---|

| Drive | kW | 4 | 5,5 | 11 | 22 | 30 |

| Speed | rpm | 8000 | 6000 | 3800 | 2400 | 1800 |

| Air flow rate | m³/h | 600 | 1200 | 3000 | 7500 | 12000 |

| Fineness | d97 mic. | 10-75 | 10-75 | 10-85 | 15-100 | 20-150 |

| Capacity | d97 mic. | - | - | - | - | - |

| 10 mic. | t/h | 0.06 | 0.12 | 0,3 | - | - |

| 20 mic. | t/h | 0.12 | 0.25 | 0,62 | 1,5 | 2,5 |

| 45 mic. | t/h | 0.2 | 0.4 | 1 | 2,5 | 4 |

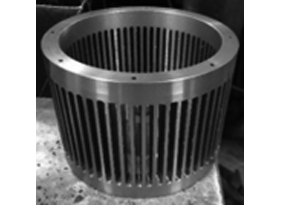

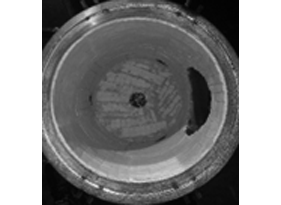

| Classifier Motor | Al2O3 Coating |

|---|---|

|

|

| With Mill Circuit | Individual Arrangement |

|---|---|

|

|

BVS Classifier Animation Video