BRM-V Classifier Mill

BRM-V Classifier Mill

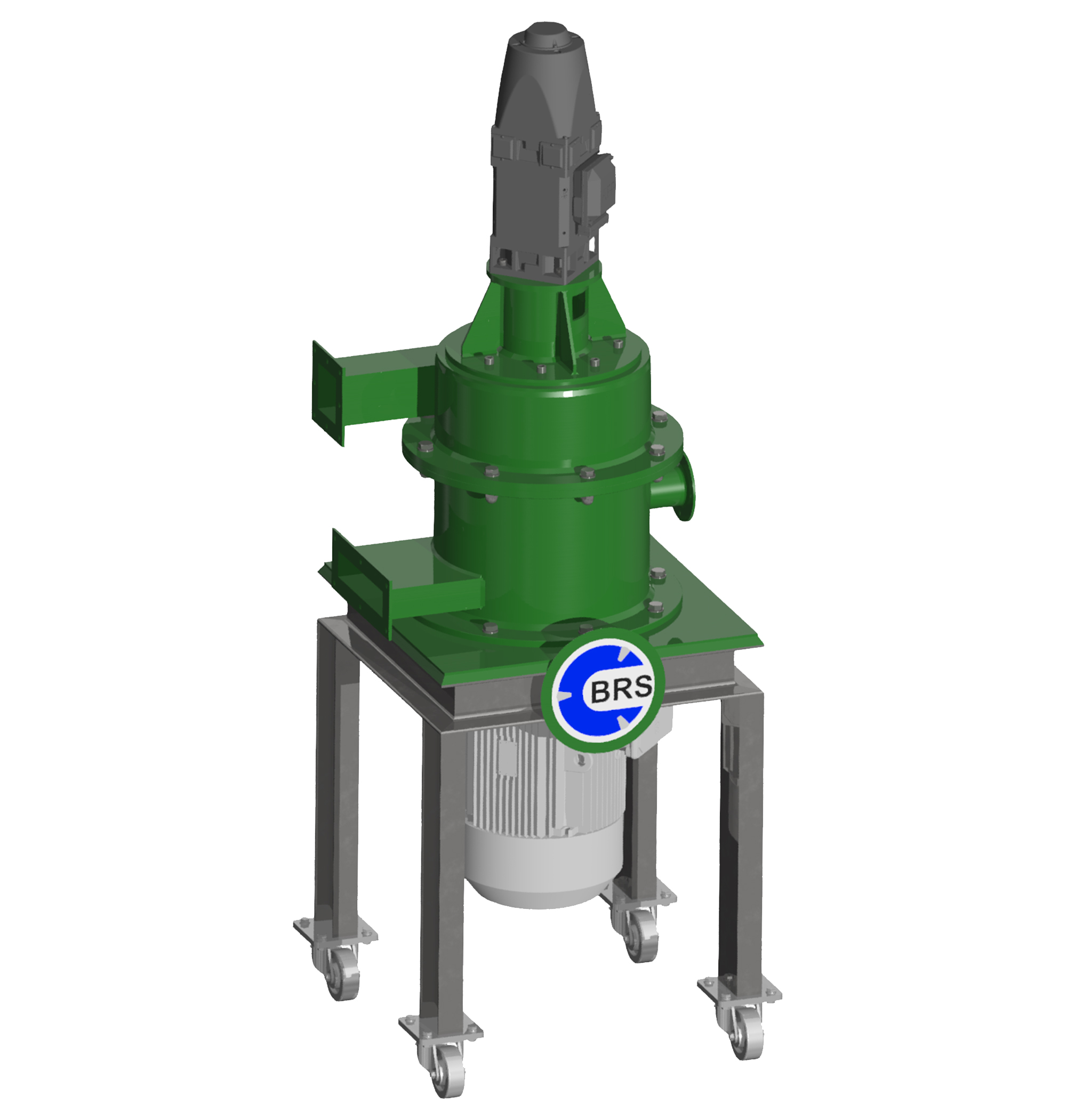

The BRM-V Classifier mill is an innovative, compact system that integrates a horizontal grinding unit and vertical classifier in a one single machine. Capable of processing materials with an input particle size of up to 15 mm, it delivers a fine and consistent output ranging from 30 to 150 μm. The system is ideally suited for a wide range of products with soft materials. When equipped with appropriately wear-resistant components, it can also handle materials with hard and abrasive material. Designed for convenience and efficiency, the machine features a pneumatic mechanism that allows the grinding and classification chamber to be opened easily, ensuring quick access for inspection, cleaning, and maintenance.

• Energy efficiency

• Compact system, occupy less area

• Easy maintenance

• Easey accessible and cleaning

• Industrial, pilot and laboratory sizes are available

• Protection against wear with steel, stainless, PU or ceramic materials (Al2O3)

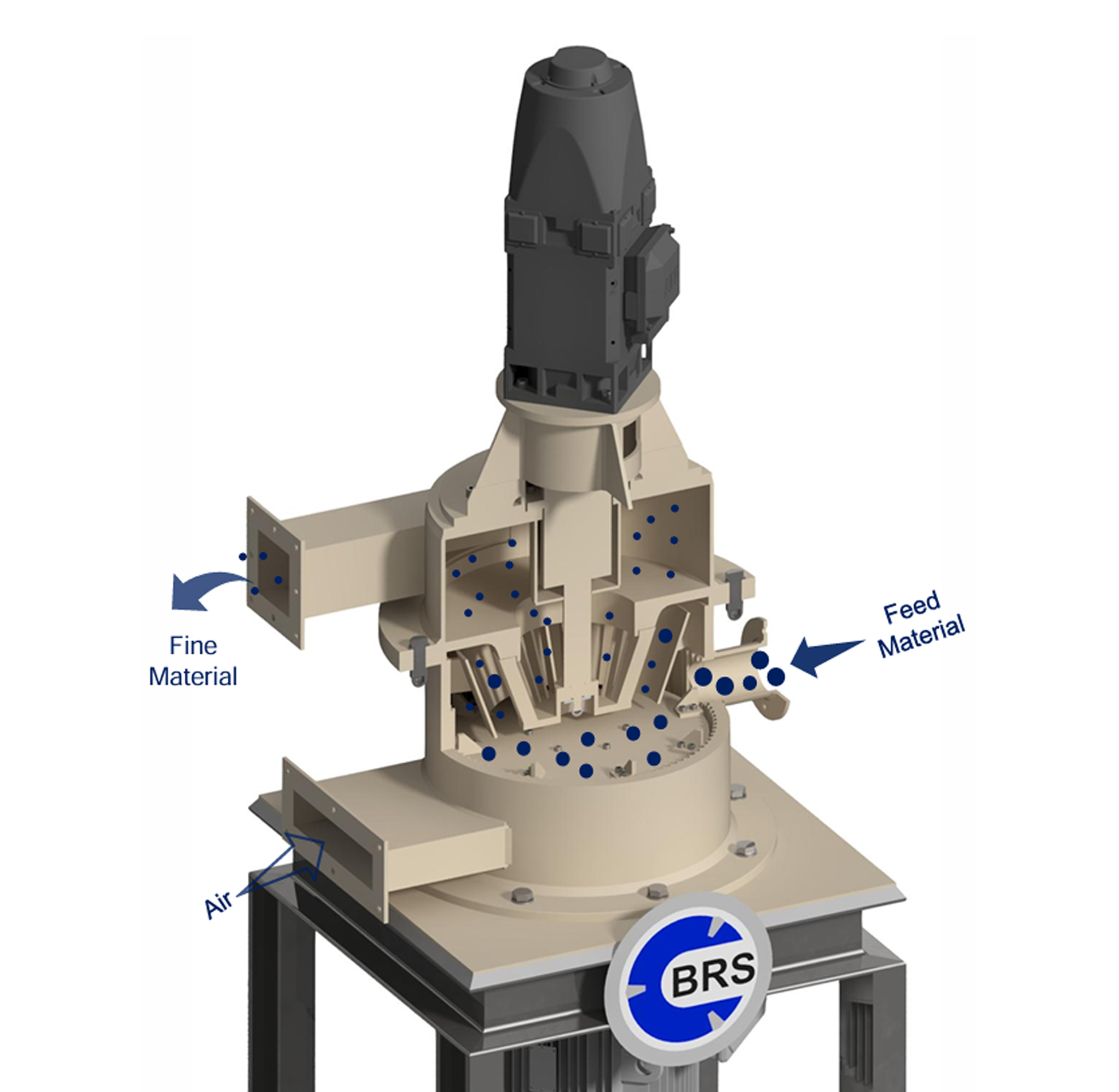

The feed material is introduced into the machine via a side-mounted feeding system or, alternatively, through an air suction, depending on the configuration. It enters the grinding chamber through feeding inlet, where it is immediately impacted by high-speed rotating grinding disc mounted on different type grinder (pins, half bar etc.). These grinders, working in conjunction with a toothed grinding track, reduce the material through a combination of impact, friction, and shearing forces. The ground particles are then transported by airflow into the integrated classifier. Here, a frequency-controlled classifier wheel separates fine particles from coarse ones based on the desired fineness. Only the particles that meet the required size—determined by the classifier wheel speed—are discharged via the fine’s outlet. Oversized particles are rejected by the classifier and returned to the grinding chamber for further milling until the target fineness is achieved. Air is introduced through a lateral inlet, playing a triple role: cooling the system, transporting the particles, and aiding in classification.

| BRM-V | Tip | BRM-V 15 | BRM-V 20 | BRM-V 30 | BRM-V 50 | BRM-V 75 |

|---|---|---|---|---|---|---|

| Rotor Drive | kW | 11 | 15 | 22 | 37 | 55 |

| Speed | rpm | 8750 | 6900 | 5750 | 4500 | 3750 |

| Air flow rate | m³/h | 1300 | 1750 | 2700 | 4650 | 6750 |

| Grinding disc | mm | 275 | 350 | 420 | 530 | 630 |

| Classifier Power | kW | 3 | 4 | 5,5 | 7,5 | 11 |

| Fineness | d95 mic. | 25-100 | 25-120 | 30-120 | 30-130 | 45-150 |

| Capacity d95 mic. | ||||||

| 15 mic. | kg/h | 20 | 25 | 40 | 65 | 100 |

| 45 mic. | kg/h | 70 | 90 | 135 | 220 | 350 |

| 100 mic. | kg/h | 150 | 200 | 300 | 500 | 750 |

BRM-H Application Area

| Minerals | Food | Chemicals | Others |

|---|---|---|---|

|

- Calcium carbonate - Diatomite - Graphite - Kaolin - Silica - Gypsum - Perlite - Talc - Wollastonite - Mica |

- Colour malt - Gelatine - Oat hulls - Lactose - Lupines - Corn - Palm fibre - Rice - Soy - Wheat germs |

- Aluminium hydroxide - Lead oxide - Calcium phosphate - Iron oxide - Sodium polyphosphate - Novolak - PE wax - Zinc oxide - Cobalt oxide |

- Toners - Coating mat. - Paints - Dentals - Pharma - Cosmetics |

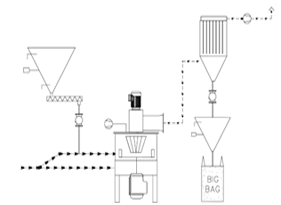

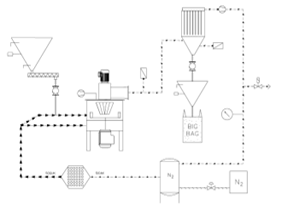

| Cicuit with no Atex | Cicuit with Atex |

|---|---|

|

|